How to Optimize Packaging for Takeout Food Quality

Takeout and delivery aren’t just side hustles for restaurants anymore — for many, they’re the backbone of their business. But here’s the truth that too many restaurant owners overlook: great food alone isn’t enough. If your packaging can’t keep that food hot, fresh, and looking good when it arrives, customers won’t think twice before ordering elsewhere next time.

Optimizing your packaging isn’t just about avoiding soggy fries or spilled soup. It’s about protecting your product, preserving your reputation, and increasing repeat orders. In fact, the right packaging can:

- Keep food at its ideal temperature

- Maintain texture and prevent sogginess

- Reduce spills, leaks, and messes

- Showcase your branding and professionalism

- Minimize food waste and maximize portion accuracy

With rising competition in the delivery market, dialing in your packaging strategy isn’t optional — it’s essential.

In this guide, I’ll walk you through the smartest, most practical ways to upgrade your packaging for takeout success. Whether you run a casual café, a bustling restaurant, or a growing cloud kitchen, these tips are tailored to help you improve food quality, boost customer satisfaction, and grow your bottom line.

Ready to turn your packaging from an afterthought into a competitive edge? Let’s get started.

Why Packaging Isn’t Just a Box: It’s Your Brand Experience

Takeout packaging does far more than simply hold food. It’s the very first physical interaction customers have with your restaurant outside your four walls. Long after the food is eaten, your packaging leaves a lasting impression — whether that’s good or bad depends on your choices. From functionality to branding, packaging plays a key role in shaping your restaurant’s image, reputation, and repeat business.

Let’s break down exactly why packaging matters so much and how it directly affects your customer experience.

The Growing Role of Takeout and Delivery

- Takeout and delivery sales have skyrocketed in recent years.

- Many restaurants now earn 30% to 60% of their revenue through off-premises dining.

- Customers expect restaurant-quality meals at home — and packaging is key to meeting that expectation.

If you’ve been treating takeout packaging as an afterthought, it’s time to reconsider. As off-premises dining becomes the norm, packaging has moved from a back-end detail to a front-line customer experience tool.

Why Packaging Shapes Customer Perception

- The packaging is the first thing customers see when their food arrives.

- High-quality, well-designed packaging signals care and attention to detail.

- Poor packaging creates a negative emotional response — before they even taste the food.

Think of your packaging as part of your plating. Customers associate messy, flimsy, or unappealing packaging with poor service, no matter how good the food inside might be.

Common Complaints That Drive Customers Away

Here are frequent packaging-related issues that frustrate customers:

- Leaking or spilling during transit

- Cold or soggy food upon arrival

- Difficult-to-open containers

- Melted or wilted ingredients

- Packaging that feels wasteful or excessive

These complaints don’t just hurt reviews — they reduce the likelihood of repeat orders. Fixing these pain points improves satisfaction and protects your restaurant’s reputation.

Real-World Example: Boosting Sales Through Better Packaging

Many restaurants have seen significant success after upgrading their packaging. One notable example:

- A fast-casual burger chain switched to ventilated containers for fries and breathable clamshells for burgers.

- They also added branded paper wraps to reduce food shifting in transit.

- The result? A 15% rise in repeat delivery orders and a noticeable drop in customer complaints.

This example proves that packaging upgrades aren’t just about aesthetics — they can directly boost your revenue. By addressing common customer frustrations, you can transform packaging into a competitive advantage.

Key Traits of Packaging That Keeps Food Tasting Fresh

Keeping food fresh during delivery isn’t just about speed — it’s about smart packaging choices. The right materials, designs, and container styles can make the difference between a soggy disappointment and a meal that tastes just as good at home as it does in your dining room.

In this section, we’ll dive into the essential packaging features that directly impact food quality and customer satisfaction.

Heat Retention Without Sogginess

- Insulation is critical for hot foods, but too much can trap steam and cause sogginess.

- The goal is to retain heat while allowing moisture to escape where necessary.

- Common solutions:

- Foil-lined paper wraps for burritos or sandwiches

- Insulated containers with vent holes for fried foods

- Double-walled containers for soups and stews

- Foil-lined paper wraps for burritos or sandwiches

Finding the balance between heat retention and breathability is crucial. The best packaging keeps food warm without sacrificing texture.

Moisture Control to Prevent Soggy Dishes

- Moisture buildup can quickly ruin crispy items like fries, wings, or tempura.

- Solutions include:

- Vented containers to let steam escape

- Absorbent paper liners inside boxes

- Separating wet and dry components (for example, dressing on the side)

- Perforated packaging for fried items

- Vented containers to let steam escape

Preventing sogginess isn’t just about keeping things dry — it’s about smart airflow and strategic separation of ingredients.

Sturdiness and Leak Protection

- Durability matters, especially for dishes with sauces, soups, or oily ingredients.

- Weak containers can crack, leak, or collapse in transit.

- Features to look for:

- Reinforced corners or double-seamed edges

- Leak-resistant lids that snap securely

- Material thickness rated for delivery travel

- Tamper-evident seals for added security

- Reinforced corners or double-seamed edges

Customers expect their food to arrive intact. A sturdy, leak-proof container prevents spills and maintains visual appeal upon opening.

Portion Control and Presentation

- Oversized containers can cause food to shift and lose its shape.

- Undersized ones can crush ingredients or cause overflow.

- Effective packaging:

- Fits the portion neatly, leaving minimal empty space

- Offers compartments to separate sides or sauces

- Includes clear lids for visual appeal and reassurance

- Keeps presentation consistent from kitchen to customer

- Fits the portion neatly, leaving minimal empty space

When packaging matches the portion precisely, it keeps food stable, attractive, and easy to serve at home. Plus, it reduces waste and keeps food costs predictable.

Matching Packaging Types to Specific Foods

Not all foods travel the same way — and not all packaging works for every dish. Choosing packaging based on the type of food you’re serving is one of the smartest ways to maintain quality, minimize complaints, and delight customers at home.

Here’s how to match the right packaging to specific menu categories for the best results.

Best Options for Fried Foods

Fried foods are notoriously tricky — they lose their crispness fast if trapped in steam.

To keep them crunchy:

- Use vented containers or packaging with built-in air holes.

- Avoid sealed plastic containers that trap steam.

- Consider kraft paper boxes with moisture-resistant linings.

- Add absorbent paper liners to soak up excess grease.

- Don’t overfill the container; allow air circulation inside.

A well-ventilated container paired with an absorbent liner can dramatically improve the quality of fried dishes like fries, onion rings, or chicken tenders during delivery.

Packaging for Soups, Curries, and Saucy Dishes

These items need packaging that can handle heat, weight, and liquids without leaking or collapsing.

Ideal solutions include:

- High-temperature plastic containers with secure snap lids.

- Double-walled paper containers for insulation and durability.

- Tamper-evident lids to prevent spills and build customer trust.

- Outer paper sleeves or bags to catch minor spills during transit.

For extremely hot or oily dishes, make sure containers are rated for both temperature and grease resistance to prevent deformation or leaks.

Salads, Cold Foods, and Desserts

Cold items have their own set of challenges — keeping them fresh without condensation or wilting.

Smart packaging choices:

- Clear plastic containers with ventilation to avoid sogginess.

- Separate compartments for toppings, croutons, or dressings.

- Compostable or recyclable containers for eco-conscious presentation.

- Small deli containers for sauces or dips on the side.

Keeping components separate until consumption ensures salads stay crisp and desserts keep their intended textures and flavors.

Multi-Component Meals and Combos

Meals with multiple items need packaging that keeps everything in place without mixing or spilling.

Best solutions:

- Bento box-style containers with divided compartments.

- Snap-on lids that keep compartments sealed tightly.

- Nesting containers for combos with separate hot and cold elements.

- Wraps or bands to bundle containers neatly for easy transport.

Multi-compartment packaging is excellent for combo meals, lunch specials, or any dishes requiring clear separation — helping you deliver both visual appeal and consistent taste across complex orders.

How to Avoid the “Soggy Fries” Problem

Few things disappoint customers more than opening their takeout bag to find limp, soggy fries. Fries are one of the most difficult items to keep crispy during delivery — but with the right packaging strategy (and a few extra precautions), you can dramatically improve their texture and quality.

Here’s how to tackle the “soggy fries” problem effectively.

Why Fries Are So Challenging for Takeout

- Fries are high in moisture and oil content, making them prone to steaming themselves during transport.

- When trapped in a sealed container, steam turns into condensation — which quickly softens crispy exteriors.

- Delivery time, stacking of containers, and even bag closure methods all worsen the issue.

Recognizing that fries naturally lose crispness without intervention is the first step toward solving this common complaint.

Packaging Solutions Designed for Crispy Fries

The right packaging can greatly improve fry quality:

- Vented fry containers or boxes — these allow steam to escape while holding heat.

- Perforated liners or bags — materials like kraft paper help absorb excess grease and moisture.

- Open-top paper fry cups or sleeves — ideal for short delivery times, offering maximum breathability.

- Corrugated cardboard trays with holes — great for large portions, balancing insulation with ventilation.

The key here is to prioritize airflow and avoid trapping moisture inside the container.

Delivery Bag Handling Tips That Make a Difference

How the food is packed for delivery matters just as much as the packaging itself:

- Never stack heavy containers (like soups) on top of fries or fried items.

- Keep fries elevated or placed on top of the delivery bag when possible.

- Use separate smaller bags for fries to allow them to breathe.

- Avoid tightly sealing the outer delivery bag — leave it slightly open to release steam.

- Instruct drivers to handle fry containers carefully and avoid cramming bags into tight spaces.

Proper bagging practices can extend fry crispness by several minutes, making a noticeable difference by the time the customer opens their order.

Pro Tips from Restaurants That Solved the Fry Problem

Many restaurants use a combination of packaging, kitchen practices, and delivery tweaks to deliver better fries:

- Double-fry technique: Fry once, cool, then fry again before packaging to create an extra-crispy exterior.

- Timing orders: Delay packaging fries until the rest of the order is ready to reduce time in transit containers.

- Offer “reheat at home” tips: Include simple instructions (like a quick oven toast) for customers who want ultimate crispness.

Fries may always be tricky, but with smart packaging and operational tweaks, you can greatly improve customer satisfaction and reduce complaints about soggy sides.

Sustainable Packaging Without Sacrificing Quality

Sustainability is no longer a niche concern — it’s a customer expectation. More diners are asking about eco-friendly packaging, and some cities now regulate or ban certain materials like Styrofoam and single-use plastics. But here’s the challenge: going green shouldn’t mean compromising food quality, durability, or aesthetics.

In this section, we’ll explore how to balance sustainability with performance — so your packaging works for both the planet and your bottom line.

Compostable vs. Recyclable: What’s Right for You?

Not all “green” packaging is created equal — and terms like compostable and recyclable often confuse business owners.

Here’s a breakdown:

- Compostable packaging:

- Made from plant-based materials like bagasse (sugarcane fiber), PLA (corn-based bioplastics), or bamboo.

- Designed to break down into natural elements under proper composting conditions.

- Works well for moist or greasy foods but may have heat limitations.

- Made from plant-based materials like bagasse (sugarcane fiber), PLA (corn-based bioplastics), or bamboo.

- Recyclable packaging:

- Typically made from paper, cardboard, or certain plastics (like PET or PP).

- Requires customers to properly sort and recycle it, depending on local rules.

- Often more heat-resistant than compostable options.

- Typically made from paper, cardboard, or certain plastics (like PET or PP).

Choosing the right option depends on your local regulations, customer habits, and the types of food you serve. Sometimes, a blend of both is the most practical route.

Sourcing Eco-Friendly Packaging That Actually Works

It’s easy to get overwhelmed by the options out there — but not every “eco” product lives up to its claims.

Here’s how to vet suppliers:

- Look for trusted certifications such as:

- BPI Certified Compostable (Biodegradable Products Institute)

- FSC Certified (Forest Stewardship Council) for paper products

- OK Compost or TÜV Austria for home compostability

- BPI Certified Compostable (Biodegradable Products Institute)

- Test packaging for:

- Durability under heat and moisture

- Leak resistance

- Sturdiness during delivery handling

- Durability under heat and moisture

- Ask suppliers for samples before committing to large orders.

Many foodservice suppliers now offer green product lines that balance sustainability and performance — but it’s critical to test them with your food, not just rely on marketing claims.

Educating Customers About Your Sustainable Choices

Even the most eco-friendly packaging won’t have much impact if customers don’t know how to dispose of it properly.

Here’s how to make your sustainability efforts visible:

- Label packaging clearly with disposal instructions (compost, recycle, landfill).

- Use QR codes or short links leading to your website’s sustainability page.

- Add branded inserts or stickers explaining your eco commitment — many customers appreciate the effort.

- Consider social media posts showing behind-the-scenes efforts like switching vendors or reducing waste.

When customers see that you’re actively working toward sustainability — without sacrificing their food experience — it strengthens loyalty and can even boost word-of-mouth referrals.

Key Tip: Watch for “Greenwashing”

Some packaging options may seem eco-friendly but aren’t as sustainable as they appear.

Common red flags:

- Terms like “biodegradable” without certifications

- Packaging that’s technically recyclable but not accepted by most municipal recycling programs

- Coated materials (like plastic-lined paper) that complicate recycling

Stay focused on solutions that truly balance environmental responsibility and practical performance — your customers (and your business) will benefit long term.

Hidden Costs and Profit Impacts of Packaging Choices

It’s tempting to focus only on the upfront price tag when selecting packaging — but doing so can cost you more in the long run. Packaging decisions have ripple effects throughout your business, from food waste and customer satisfaction to delivery complaints and repeat sales.

In this section, we’ll break down the hidden costs and bottom-line impacts of packaging — and why spending a little more upfront often pays off.

Why Cheaper Isn’t Always Cheaper

Low-cost packaging often leads to:

- Higher food waste: Poor insulation or leaks can ruin meals, forcing refunds or replacements.

- Increased complaints: Customers may avoid reordering if their food arrives cold, soggy, or spilled.

- Operational headaches: Fragile or awkward packaging slows down your staff and delivery drivers.

- Damage to your brand: Cheap-looking or ineffective packaging can harm your restaurant’s image, especially on social media.

While you might save a few cents per unit, those “savings” are easily wiped out by lost customers, refunds, and negative reviews.

The True Cost of Packaging Per Order

To understand the real financial impact, you need to look beyond per-unit pricing and consider:

- Cost per order: Factor in how many containers, bags, utensils, and napkins you use per order.

- Wastage: Include costs for packaging that arrives damaged or isn’t used due to quality issues.

- Staff time: Consider how long it takes to assemble and pack orders with different packaging types.

- Delivery replacements: Track the number of redeliveries or refunds tied to packaging failures.

Example:

Paying $0.40 more per container may seem high, but if it cuts refunds and boosts repeat orders by even 5% to 10%, it often pays for itself.

Packaging’s Role in Customer Retention and Sales

Good packaging doesn’t just protect food — it subtly encourages repeat business:

- Better first impressions: Customers are more likely to reorder from places where food arrives well-presented and intact.

- Brand loyalty: Unique, attractive packaging increases memorability, especially for Instagram-worthy meals.

- Perceived value: Premium packaging can justify higher menu prices or delivery fees.

Many restaurants report higher lifetime customer value (LTV) after upgrading packaging — because customers trust them to deliver consistent quality, every time.

A Practical Tip for Restaurant Owners

Start tracking these packaging-related metrics:

- Number of refund requests related to packaging issues

- Customer reviews mentioning packaging (positive and negative)

- Time spent on packing orders

- Average cost of packaging per order

Once you start viewing packaging as a profit lever instead of just an expense, it becomes easier to justify smart upgrades that improve both your customer experience and your bottom line.

Testing Your Packaging Like a Pro

Choosing packaging isn’t just about reading product descriptions or going with what your supplier recommends. To truly protect food quality and customer satisfaction, you need to test your packaging the same way your customers experience it — during real-world delivery scenarios.

Here’s how to thoroughly test packaging like a seasoned restaurant pro before rolling it out.

Simulating Real-Life Delivery Scenarios

Your packaging might seem great in the kitchen, but it needs to survive the entire journey from kitchen to doorstep. Here’s how to test:

- Time Trials: Pack typical orders and let them sit for 20 to 40 minutes (the average delivery window) before opening them.

- Temperature Tests: Use a basic food thermometer to track how much heat is lost over time.

- Moisture Checks: Watch for condensation inside containers, especially with fried or crispy items.

- “Shake” Tests: Gently shake or tilt packaged meals to mimic handling by delivery drivers.

- Bagging Practice: Pack orders the same way your staff would during busy shifts to spot weak points in your process.

If your packaging doesn’t keep food fresh, intact, and presentable after a typical delivery duration, it’s not ready for rollout.

Involving Your Staff in Packaging Decisions

Your front-line employees have valuable insights when it comes to packaging. Involving them can improve both operational flow and food quality.

Here’s how to include them:

- Ask kitchen staff to identify packaging that slows them down or doesn’t hold up under pressure.

- Have delivery drivers report on packaging that leaks, tears, or causes customer complaints.

- Encourage FOH (front-of-house) staff to suggest packaging that looks more presentable or is easier to handle.

When your team is involved in packaging decisions, they’re more likely to pack orders consistently and flag potential issues before they impact customers.

Gathering Customer Feedback Effectively

The ultimate test of packaging comes from your customers. Gathering their feedback can help you fine-tune your packaging choices.

Here’s how to collect it:

- Add a QR code or link on packaging that leads to a short feedback survey.

- Ask questions like:

- Did your food arrive hot and fresh?

- Was the packaging easy to handle and open?

- Would you order this item again for delivery?

- Did your food arrive hot and fresh?

- Offer a small incentive (like a discount code) for completing the survey.

- Monitor delivery platform reviews for packaging-related comments — both good and bad.

Don’t forget to act on what you learn. If you receive repeated comments about soggy items or tricky containers, make adjustments quickly.

Bonus Tip: Test Across Different Seasons

Packaging that works well in mild weather may not hold up in extreme heat or cold. Test your containers during:

- Hot, humid summer days (when condensation issues peak)

- Cold winter months (when food cools rapidly)

This helps you avoid surprises — and customer complaints — throughout the year.

By putting your packaging through rigorous, realistic testing, you’ll save yourself headaches later and deliver a consistently excellent takeout experience every time.

Smart Labeling and Branding That Boosts Sales

Your packaging isn’t just about holding food — it’s also valuable marketing real estate. Smart labeling and thoughtful branding can make a lasting impression on customers, enhance the takeout experience, and even drive more orders.

Here’s how to use your packaging to build loyalty, boost sales, and streamline your operations at the same time.

Practical Labeling Tips for Smooth Operations

Labeling isn’t just about branding — it also plays a huge role in operational efficiency and customer satisfaction.

Key labeling tips include:

- Clear Item Names: Use large, easy-to-read text for order accuracy, especially for combo meals or large family orders.

- Allergen Notices: Highlight common allergens clearly to prevent health risks and improve transparency.

- Reheating Instructions: Include microwave, oven, or air-fryer directions for items that benefit from a quick refresh at home.

- Prep Time Stamps: Add a sticker with the order time and date to reassure customers about freshness and streamline order tracking.

Simple, clear labels can dramatically reduce mix-ups, help customers enjoy their meals properly, and minimize post-order complaints.

Turning Packaging Into a Marketing Tool

Every takeout order is an opportunity to reinforce your brand and encourage repeat business. Thoughtful branding doesn’t have to be expensive — it just needs to be intentional.

Here’s how to make your packaging work harder for you:

- Custom Stickers or Stamps: Affordable and easy to apply on bags, boxes, or cups.

- Branded Tape or Seals: Adds a tamper-evident feature while reinforcing your logo and colors.

- Printed Bags or Containers: Higher upfront cost, but excellent for long-term brand recognition and social media photos.

- Social Handles or QR Codes: Direct customers to your website, loyalty program, or delivery app page right from the package.

When customers recognize your packaging, it increases the chances they’ll remember your restaurant next time they’re hungry — and they may even share photos on social media.

Creative Extras That Delight Customers

Going beyond the basics can help you stand out and create memorable customer moments.

Here are a few simple extras to consider:

- Handwritten Notes: A quick “Thank You!” or a personalized message feels authentic and adds warmth.

- Loyalty Punch Cards: Easy to slip into takeout bags; encourage return visits or larger orders.

- Coupons or Discounts: Incentivize future orders with a time-limited promo code or offer.

- Seasonal Inserts: Celebrate holidays, share upcoming promotions, or feature limited-time dishes.

These small touches often cost less than $0.50 per order, but they can make customers feel valued and encourage repeat business.

Pro Tip: Keep It Cohesive

While creative packaging can boost sales, it’s important to keep it consistent with your overall brand identity:

- Match your fonts, colors, and logo across all packaging.

- Keep the messaging tone aligned with your restaurant’s personality — whether casual, upscale, playful, or sophisticated.

- Don’t overcrowd your packaging; clean, simple designs often have the most impact.

When branding, labeling, and packaging work together seamlessly, your takeout orders become an extension of your restaurant’s in-house dining experience — boosting both customer satisfaction and long-term loyalty.

Quick Checklist: Is Your Takeout Packaging Doing Its Job?

Sometimes, the simplest way to evaluate your takeout packaging is to run through a clear, no-nonsense checklist. This quick test helps you spot weaknesses in your current setup — and ensures every order leaves your kitchen ready to impress.

Here’s your go-to packaging performance checklist:

✅ Heat Retention

- Does the packaging keep hot items warm for at least 30 minutes?

- Are vent holes or breathable features present to avoid sogginess where needed?

- Does it balance insulation without over-steaming fried or crispy foods?

✅ Moisture Management

- Does the packaging prevent excessive condensation buildup?

- Are fried or crispy items staying crunchy during typical delivery times?

- Are there paper liners or vented containers for moisture-sensitive dishes?

✅ Structural Integrity

- Is the packaging strong enough to handle full portions without collapsing or leaking?

- Does it hold up during stacking and transit?

- Are lids secure enough to prevent spills and shifts?

✅ Environmental Responsibility

- Is the packaging recyclable, compostable, or made from renewable materials?

- Are you using minimal packaging without compromising quality?

- Do you provide clear disposal instructions for customers?

✅ Customer-Friendliness

- Is the packaging easy to open without spilling?

- Are labels clear and helpful (item names, allergens, reheating instructions)?

- Is the packaging attractive and aligned with your brand’s image?

✅ Branding & Marketing Impact

- Does the packaging reinforce your restaurant’s branding through design, stickers, or labels?

- Are there loyalty cards, coupons, or thank-you notes included when appropriate?

- Is your website or social media handle visible for future orders?

✅ Cost-Effectiveness

- Are you tracking packaging cost per order, including hidden costs like refunds or replacements?

- Does the packaging reduce food waste or increase efficiency?

- Are you seeing fewer complaints and higher repeat order rates after packaging updates?

How to Use This Checklist:

Review this list every few months, especially if you’re adding new menu items or changing delivery platforms.

If you’re answering “no” to multiple points, it’s time to reassess your packaging strategy.

Great packaging isn’t a “set it and forget it” task — it’s a crucial part of keeping customers happy, protecting your margins, and growing your business.

Where to Source Top-Quality Packaging Suppliers

Finding the right packaging supplier can feel overwhelming — especially with so many options claiming to offer the “best” solution. But sourcing high-quality, reliable packaging isn’t just about picking the cheapest vendor or the flashiest website. It’s about finding a supplier that meets your food’s specific needs, your budget, and your operational demands.

Here’s how to identify trustworthy packaging partners and make smarter purchasing decisions.

Key Questions to Ask Before Choosing a Vendor

Before committing to any supplier, make sure you ask these essential questions:

- What’s the lead time on orders? (Speed matters during busy seasons or supply chain disruptions.)

- Do they offer samples for testing? Never skip testing packaging with your actual menu items.

- Are their products certified as compostable, recyclable, or food-safe? Look for official certifications like BPI, FSC, or FDA-compliance.

- Can they customize packaging for your branding? Branded packaging options can streamline your marketing.

- What’s the minimum order quantity (MOQ)? Some suppliers have high MOQs that may not suit smaller operations.

- Do they offer volume discounts or loyalty programs? Long-term partnerships often lead to better pricing.

Asking these questions upfront prevents costly surprises down the road.

Domestic vs. Imported Suppliers — What to Consider

Both local and international suppliers come with advantages and drawbacks.

Domestic Suppliers:

- Faster shipping and easier returns

- Easier to communicate with (especially if customization is needed)

- More predictable delivery timelines

- Often aligned with local regulations for compostable/recyclable packaging

Imported Suppliers (often from Asia or Europe):

- Lower per-unit costs (especially on bulk orders)

- Wider variety of styles, finishes, and materials

- Longer lead times and potential customs delays

- Higher shipping costs that can offset product savings

Pro Tip:

If you’re just starting out or need packaging fast, stick with domestic sources first. Once your needs stabilize, you can explore bulk imports for potential savings.

Recommended Packaging Marketplaces and Suppliers

Here are some well-known and trusted places to start your packaging search (always confirm local availability):

US-Based Suppliers:

- WebstaurantStore: Wide range of foodservice packaging; fast shipping

- Eco-Products: Specializes in compostable containers and utensils

- PacknWood: Stylish, eco-friendly options for high-end restaurants and cafes

- Uline: Bulk pricing with fast delivery on many packaging basics

UK & EU-Based Suppliers:

- Biopak UK: Compostable, recyclable packaging focused on sustainability

- Vegware: Popular for plant-based, certified compostable solutions

- Cater4You: Broad selection of affordable takeaway packaging

- BBP Marketing: Custom-branded packaging options

Global Marketplaces:

- Alibaba: Wide range of custom and bulk packaging — ideal for large orders but requires careful vetting

- Faire: Wholesale marketplace connecting small businesses to verified suppliers

Bonus Tip:

Check with your local foodservice distributors — many now carry sustainable and branded packaging lines alongside their usual inventory.

Final Advice on Sourcing

- Start small with initial orders to test quality and service.

- Build relationships with your reps — they can alert you to new products or discounts.

- Always track your costs, including shipping, storage space, and waste reduction, to assess true value.

Reliable packaging suppliers aren’t just vendors — they’re partners in your restaurant’s long-term success. Choose wisely, and your packaging will work harder for you every step of the way.

Key Takeaways

Optimizing your takeout packaging isn’t just about keeping food intact — it’s about protecting your customer experience, enhancing your brand, and boosting your bottom line. Here are the key takeaways from this guide to help you make smarter packaging decisions:

- Packaging is more than just a container — it’s part of your customer’s dining experience and directly affects satisfaction, reviews, and repeat business.

- Focus on packaging that preserves heat and texture by using materials that balance insulation and ventilation, especially for fried or crispy foods.

- Match your packaging to the type of food you serve — soups, salads, fried items, and combo meals all require different solutions to maintain quality.

- Solve the soggy fries problem by using vented containers, absorbent liners, and smart bagging techniques to keep fries crispy longer.

- Sustainable packaging is possible without sacrificing quality — choose compostable or recyclable options that align with your brand and local regulations, and educate customers on how to dispose of them properly.

- Consider the hidden costs of packaging, including food waste, refunds, customer loss, and operational slowdowns. Premium packaging often delivers better ROI than cheaper alternatives.

- Test your packaging under real-world conditions before committing to large orders. Simulate delivery times, involve your staff, and gather customer feedback regularly.

- Leverage smart labeling and branding to boost customer loyalty, streamline operations, and increase marketing reach through every takeout order.

- Source suppliers carefully by asking key questions, comparing local vs. imported options, and testing products thoroughly before scaling up.

The right packaging can transform your takeout and delivery business from good to great — and it all starts with making intentional, well-tested choices.

Frequently Asked Questions About Optimizing Takeout Packaging for Restaurants

To help restaurant owners and managers get the most out of their takeout operations, we’ve answered some of the most common questions about packaging quality and best practices. Whether you’re trying to reduce food leakage, keep meals hot, or improve sustainability, these FAQs offer actionable insights to enhance your customer experience.

What type of packaging keeps takeout food hot and fresh the longest?

Insulated containers, foil wraps, and vented clamshells are best for maintaining temperature and freshness. Look for packaging with built-in heat retention features and moisture barriers to prevent sogginess or drying out.

How can I prevent food from getting soggy during delivery?

Use vented packaging for fried and crispy items to allow steam to escape. Separate wet and dry components (e.g., sauces on the side), and choose breathable materials like kraft paper or vented cardboard where appropriate.

What are the best eco-friendly packaging options for takeout?

Sustainable options include compostable containers made from bagasse (sugarcane fiber), biodegradable kraft boxes, and recyclable paper or cardboard materials. Avoid plastic where possible and clearly label packaging for disposal instructions.

How does takeout packaging impact customer satisfaction and reviews?

Well-designed packaging enhances the overall experience by ensuring food arrives intact, at the right temperature, and visually appealing. Poor packaging often leads to complaints, bad reviews, and repeat order loss—making quality packaging a direct driver of customer loyalty.

Should I brand my restaurant’s takeout packaging?

Yes. Custom-branded packaging reinforces your identity, builds trust, and boosts recall for repeat orders. Even simple branded stickers, bags, or printed boxes can turn takeout into a marketing tool, especially when shared on social media or reviewed online.

ABOUT THE AUTHOR

Erkin Coban

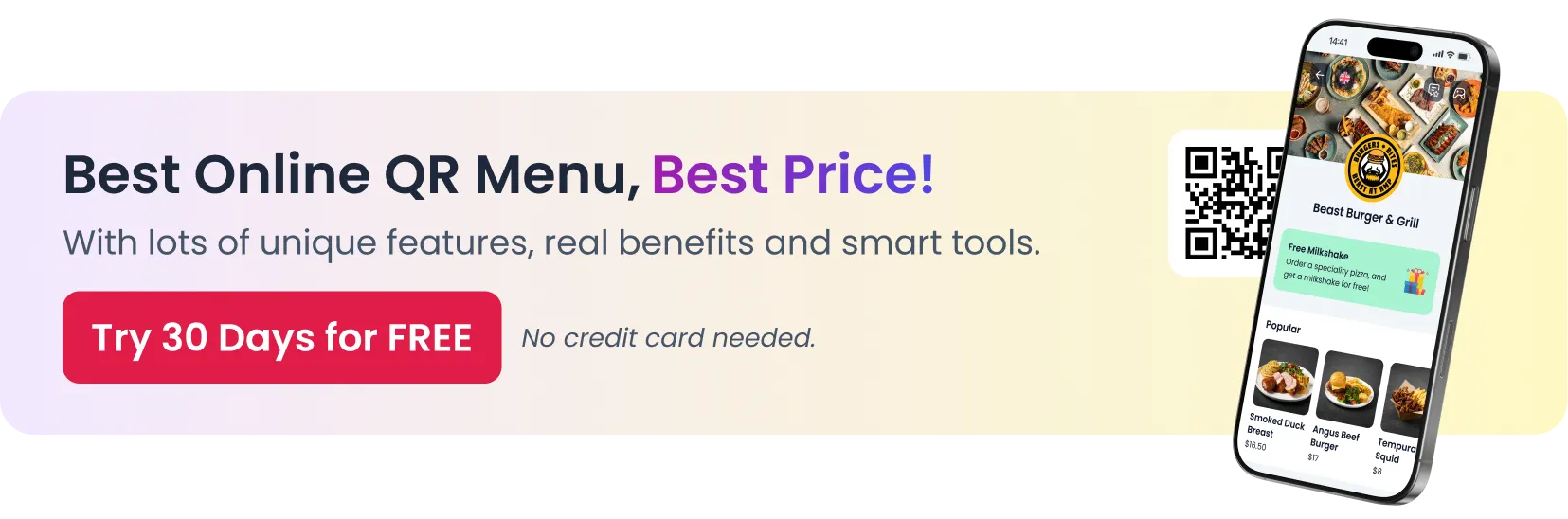

Your Customers Deserve The Best

And we got Menuviel for them.

The fastest and easy-to-use online QR menu with 12+ unique features. Choose Menuviel and elevate your service quality to the next level.

Use free for the first 30 days.

In This Article

Free AI Tools for Restaurants

TRY NOW ➜

Lightning-fast loading pages and images

Your menu loads instantly with optimized images—no waiting, just a smooth browsing experience.